To use a scanner preventive maintenance schedule effectively, we should first establish inspection intervals based on manufacturer recommendations. Let’s prioritize tasks like cleaning and calibrating the scanner semi-annually. By tracking historical data, we can optimize schedules to prevent excessive downtime. Regularly updating software also enhances functionality. With efficient communication and documentation, we can quickly address issues, enhancing equipment reliability. If we continue, we’ll uncover more strategies for improving our scanner maintenance process.

Key Takeaways

- Align your maintenance schedule with manufacturer recommendations to ensure optimal equipment performance.

- Assess scanner criticality and schedule at least two inspections annually to prevent unexpected downtime.

- Use historical data to adjust maintenance intervals based on past performance and equipment usage.

- Clearly outline maintenance tasks and provide necessary tools to streamline the process during low-use periods.

- Regularly communicate findings and utilize digital dashboards for monitoring and improving equipment efficiency.

Understanding the Importance of Preventive Maintenance

When we consider the importance of preventive maintenance, it’s clear that it serves as the backbone of operational efficiency. By implementing preventive strategies, we can identify equipment issues before they turn into costly failures. Regular maintenance not only reduces unexpected downtime but also stabilizes our production schedules. Studies indicate that predictive maintenance can reduce machine downtime by 30% to 50%, greatly boosting productivity. Additionally, well-maintained equipment enhances reliability, adding up to 20% to 40% to its lifespan. This maintenance significance extends beyond just equipment; it also contributes to cost savings, with businesses saving about 12% to 18% on total maintenance expenses. Ultimately, preventive maintenance fosters a smoother workflow, ensuring our operations run as efficiently as possible. Regular use of cleaning cards can significantly improve performance and extend the lifespan of your equipment.

Typical Tasks Involved in Scanner Maintenance

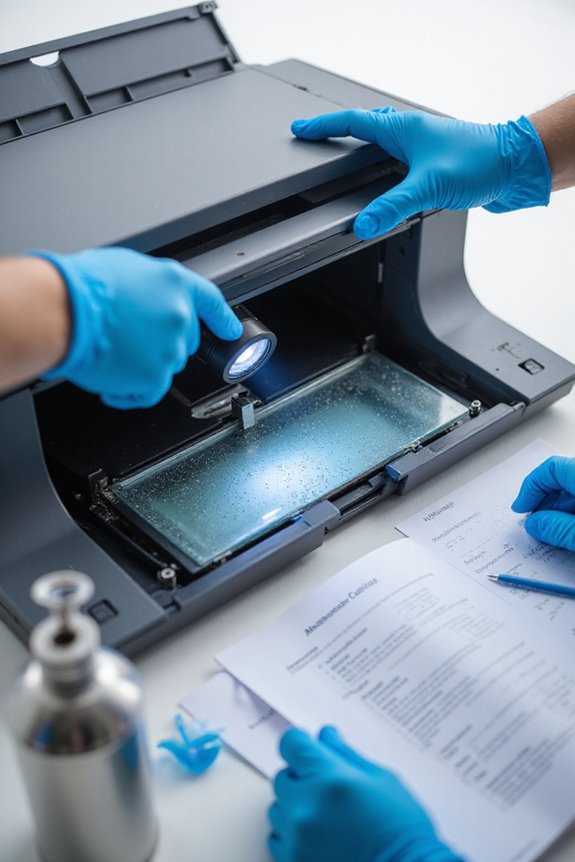

Maintaining a scanner involves several essential tasks that guarantee peak performance and longevity. First, we need to prioritize scanner cleaning; regularly cleaning the glass and backing layer keeps our scans sharp and clear. Make certain to use manufacturer-recommended fluids and avoid water or rubbing alcohol. Next, we can’t overlook the importance of calibration procedures. Regularly calibrating our scanner guarantees accurate color reproduction and image quality. Performing test scans helps us check for any distortions or clarity issues. Together, let’s adjust settings based on these tests to optimize our performance. Additionally, implementing regular maintenance with cleaning solutions containing Isopropyl Alcohol will help prevent dust buildup and enhance overall print clarity. Finally, let’s not forget to keep our software updated and monitor for any errors. By staying on top of these tasks, we’ll greatly improve our scanner’s functionality and lifespan.

Establishing a Preventive Maintenance Schedule

To guarantee our scanners operate at peak performance, establishing a preventive maintenance schedule is essential. Through careful preventive scheduling, we can align maintenance planning with manufacturer recommendations and actual scanner usage. We should assess the criticality of our scanners, aiming for at least two inspections annually for complex models. It’s wise to use historical data to tweak maintenance intervals, ensuring we avoid excessive downtime. Each task needs clear instructions, along with necessary tools and parts, so we’re always prepared. Additionally, scheduling during low-use periods helps minimize disruption. By tracking our maintenance efforts and coordinating with facility activities, we can boost efficiency, extend our scanner lifespan, and improve imaging accuracy over time. Regular cleaning of scanner glass is crucial to prevent dirty glass from affecting scan quality.

Pre-Maintenance Assessment and Preparation Steps

Before diving into maintenance, we should thoroughly assess and prepare our scanners to guarantee peak performance. First, let’s inspect the scanner exterior for any damage and make sure connections are secure. We need to check calibration logs for compliance, while cleanliness of lenses and trays is critical to avoid contamination. Next, let’s evaluate our environment—ambient temperature and humidity should be within operating ranges for ideal scanner performance. We should also update any firmware and run diagnostic tests, noting any error logs. Finally, verifying all safety features and assembling documentation is key. These preparation steps enhance equipment longevity, minimizing downtime while making certain our scanners operate efficiently, which ultimately benefits our workflow and patient care. Regular checks for signs your scanner needs cleaning can also help maintain optimal performance.

Integrating Uninterruptible Power Supply in Maintenance Planning

Integrating an Uninterruptible Power Supply (UPS) into our maintenance planning can greatly enhance the reliability of our equipment. By focusing on UPS integration, we minimize unplanned downtime, safeguarding sensitive devices from power surges and interruptions. Routine UPS servicing can double battery life, while regular checks maintain consistent power quality vital for precision equipment like scanners. This proactive maintenance optimization decreases emergency repair needs, lowering overall costs. We can also leverage predictive data to schedule planned downtimes effectively, preserving workflow continuity. Additionally, aligning UPS maintenance with critical equipment schedules guarantees that we’re maximizing operational efficiency while minimizing risks associated with unexpected outages. By prioritizing UPS maintenance, we effectively enhance our equipment’s performance and longevity across our operations. Furthermore, ensuring that we maintain our scanners properly, like the HP ScanJet series, can significantly improve their lifespan and scanning quality.

Steps for Conducting Effective Maintenance

Effective maintenance is essential for guaranteeing that our scanners operate at peak performance and longevity. To start, we should conduct biannual inspections to assess mechanical, electrical, and cooling subsystems. This proactive approach boosts scanner efficiency and prevents unexpected downtimes. Using maintenance tools, we can verify gantry rotation and inspect high-tension cables, replacing any that show wear. Regular cleaning of optical components is critical, as dirt can degrade image quality. We also need to maintain a clean environment with controlled humidity. Keeping our software updated is important for performance improvements and security. By scheduling calibration sessions, we guarantee imaging accuracy, helping us achieve consistent results. Additionally, understanding the importance of OCR technology can significantly enhance document management and retrieval. These steps create a solid foundation for effective maintenance that benefits everyone involved.

Post-Maintenance Actions and Documentation

Post-maintenance actions are vital for guaranteeing that our scanners continue to function at their best. After each maintenance session, we should conduct thorough post-maintenance cleaning, confirming the scanner glass and white backing layer are free from residue. Using manufacturer-recommended cleaning solutions helps us maintain image clarity. We need to inspect feed rollers for dust and wear, cleaning them gently with a damp cloth. It’s also important to document every maintenance action. We record the date, time, and details of tasks completed to keep accurate maintenance documentation. This helps us track the scanner’s condition for future reference. By agreeing on these actions, we guarantee our scanners operate efficiently and effectively over time.

Benefits of Adhering to OEM Recommendations

When we adhere to OEM recommendations, we reveal a range of benefits that directly enhance our equipment’s performance. Following these guidelines can increase equipment longevity by 20% to 40%, preventing premature wear and reducing stress on components. Regular maintenance guarantees our equipment operates within intended parameters, minimizing mechanical failures and costly repairs. By maintaining safety protocols, we also reduce the risk of sudden malfunctions that might lead to workplace accidents. Early identification of faults allows us to extend the overall serviceable life of our machines. This not only guarantees compliance with industry standards but also leads to better forecasting of parts, resulting in cost savings of 12% to 18% on maintenance. It’s a smart choice for every operation.

Communicating Findings for Continuous Improvement

Clear, ongoing communication helps us maximize the benefits of our scanner maintenance efforts. By sharing maintenance findings promptly, we can address issues before they lead to downtime. Standardized reporting and data sharing enhance our understanding, allowing us to identify recurring faults across PM cycles. Establishing feedback loops guarantees we gather insights from operators, integrating their experiences with technical findings for a thorough view. Using tools like CMMS and digital dashboards, we can visualize performance metrics, facilitating informed decision-making. Regular meetings to review our scanner’s status keep everyone aligned, and encourages accountability. Ultimately, this approach not only enhances our scanner’s efficiency but also improves patient care through consistent and reliable equipment availability.

Frequently Asked Questions

How Can I Track Maintenance Costs Over Time?

To track maintenance costs over time, we can utilize maintenance tracking software. This enables effective cost analysis by categorizing expenses, monitoring trends, and allowing us to plan better for future maintenance needs.

What Tools Are Essential for Effective Preventive Maintenance?

When we think about effective preventive maintenance, essential tools include a solid maintenance checklist and various preventive tools like multimeters and specialized cleaning solutions, ensuring our equipment remains in excellent condition and performs reliably.

How to Train Staff on Maintenance Procedures?

In the garden of knowledge, we cultivate growth through staff workshops and rich maintenance manuals, nurturing skills like seedlings. Together, we’ll empower our team, ensuring they flourish in their preventive maintenance journey.

What Should I Do if Issues Arise Between PM Visits?

If issues arise between PM visits, we should promptly implement troubleshooting techniques like checking connections and cleaning components. Quick issue resolution can minimize downtime and guarantee our scanner operates efficiently until the next maintenance.

How Can I Ensure Compliance With Regulatory Requirements?

To guarantee compliance with regulatory requirements, we’ll conduct regular compliance checks and maintain thorough documentation for regulatory audits. This includes securing sensitive data, implementing strict access controls, and continuously monitoring our scanning systems.