To use automatic color detection effectively, we need to understand key principles like RGB measurement and calibration techniques. We rely on RGB photodiodes for accurate color discrimination, while consistent illumination from white LEDs boosts measurement reliability. In applications like food quality control or packaging, these sensors help maintain color consistency. By compensating for environmental factors and utilizing advanced algorithms, we enhance detection accuracy. Keep exploring to discover more about the exciting future of color detection technology.

Key Takeaways

- Select the appropriate color detection system that incorporates RGB photodiodes and filters for accurate color discrimination under controlled lighting conditions.

- Position calibration targets like the Macbeth Color Checker in stable locations to ensure reliable and consistent color readings.

- Utilize white LEDs for consistent illumination, minimizing ambient light variations that can affect color detection accuracy.

- Implement calibration routines to adapt the system’s output based on varying distance and environmental conditions for optimal results.

- Leverage color detection applications across industries, such as quality control in manufacturing and crop monitoring, to enhance operational efficiency.

Understanding Color Detection Principles

Understanding color detection principles is vital for anyone looking to utilize this technology effectively. Color detection involves illuminating an object with light that contains red, green, and blue components. The reflected light is measured to determine the object’s color, relying on the principles of color perception and wavelength sensitivity. A white light source helps achieve accurate readings, while filters eliminate unwanted wavelengths like infrared and ultraviolet. By measuring the intensity of reflected light in each RGB band, we can compute the color ratios. This process allows us to identify colors accurately, even on varied surfaces. Utilizing these principles guarantees reliable color measurements in our applications, ultimately enhancing our ability to work with color detection systems effectively. Additionally, understanding OCR technology can further improve the accuracy of scanned color documents by enhancing text recognition capabilities.

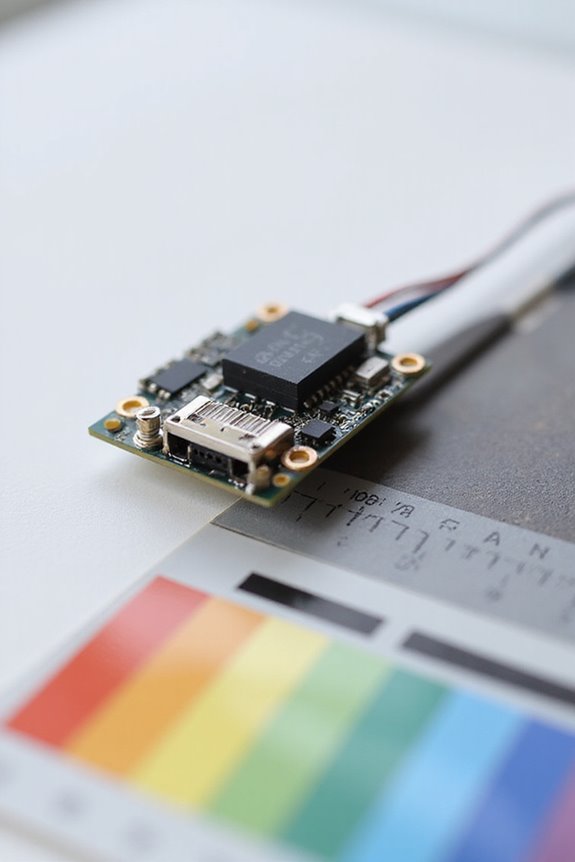

Essential Components for Color Sensors

Any effective color detection system hinges on its components, particularly the sensors that facilitate accurate measurements. The core of these systems lies in sensor components like photodiodes, especially RGB photodiode types. These photodiodes measure red, green, and blue light separately, ensuring precise color discrimination. To enhance accuracy, they often come integrated with RGB filters and IR cut filters, which block unwanted wavelengths, isolating the visible spectrum. Consistent illumination from white LEDs plays a crucial role too, as it standardizes measurements against varying ambient light conditions. In addition, analog-to-digital converters deliver processed data to microcontrollers, enabling quick interpretation of colors. Calibration routines further fine-tune the output, adapting to both distance and ambient lighting for reliable performance in color detection applications. Furthermore, high optical resolutions can enhance the detail captured in color detection, similar to how they benefit network scanners in document handling.

Applications of Automatic Color Detection

While automatic color detection may seem like a niche technology, its applications span across multiple industries, proving essential for quality control and process efficiency. In the food industry, it evaluates the browning of baked goods, ensuring uniform cooking. The automotive sector relies on color detection for inspecting parts, maintaining strict quality assurance. In electronics, sensors check LED colors, verifying functionality, while in packaging, color consistency on cosmetic bottles enhances brand reliability. Beyond these, healthcare applications, like monitoring skin color for diagnostics, showcase its versatility. Each industrial application helps streamline processes, reduce errors, and maintain high standards, demonstrating the incredible value of integrating automatic color detection into our operations. Therefore, we embrace enhanced accuracy and efficiency across various fields. Additionally, the use of automatic color detection can significantly improve the quality control processes in manufacturing, ensuring consistent product standards.

Integrating Color Detection With Computer Vision

Automatic color detection lays the groundwork for integrating advanced computer vision techniques. By utilizing color segmentation methods, we can effectively analyze visual data and enhance object recognition. This integration is particularly beneficial for real-time processing, making it possible to identify and track objects with impressive accuracy. Using frameworks like OpenCV, we can implement robust algorithms that adjust for varying lighting conditions, ensuring reliability in diverse environments. Furthermore, these algorithms facilitate efficient pixel processing, which translates visual information into actionable insights. The combination of color detection and computer vision not only boosts performance in applications like autonomous vehicles but also opens doors for innovative uses across multiple industries, ultimately improving accuracy and automation. Additionally, the use of high-density point cloud data can further enhance the precision of object detection in complex environments.

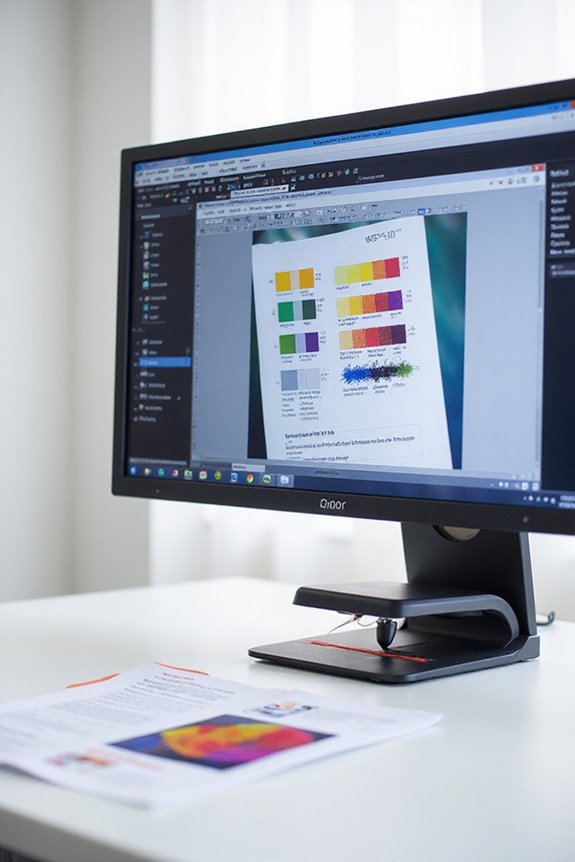

Calibration Techniques for Accurate Measurements

To guarantee accurate color measurements, selecting the right calibration targets is essential. Standardized color charts, like the Macbeth Color Checker, provide reference colors with known spectral values. We should position these targets in stable, consistent locations under controlled lighting, ensuring even illumination to minimize shadows. Capturing images of the target with each camera helps in recording their color responses. Employing effective calibration methods increases our color accuracy markedly. By using geometric techniques, we can automatically detect and align color patches, enhancing efficiency. Additionally, compensating for environmental factors like ambient lighting further stabilizes our measurements. With these calibration techniques, we’re setting the stage for consistent and reliable color detection across various devices. Furthermore, utilizing document management systems can streamline the organization of color data and ensure easy access to calibration results.

Workflow for Implementing Color Detection

Implementing a workflow for color detection isn’t just about technology; it’s about guaranteeing accuracy and efficiency across our processes. First, we capture images in RGB format and preprocess them for clarity, which often involves resizing or noise reduction. Next, we employ color detection algorithms, like k-means clustering, to identify predominant color regions and segment them. Calibration tools, such as color matching cards, help correct any shifts in color perception. We extract color data, storing it systematically for comparative analysis against standards. Finally, by focusing on user interface design, we guarantee seamless integration with existing production workflows. This structured approach enhances our accuracy, reduces errors, and creates a foundation for future automation. Additionally, integrating features from advanced functionalities can further optimize the detection process and improve overall efficiency.

Challenges in Color Detection Accuracy

After establishing a solid workflow for color detection, we now need to address the challenges that can impede accuracy. Color variance caused by environmental lighting, such as LEDs or sunlight, often misleads detection algorithms. Those algorithms may struggle under mixed light sources, leading to inconsistent recognition. Furthermore, colors with similar spectral properties can result in overlapping representations, confusing the differentiation process. While we can achieve high detection rates with statistical models, false positive rates can still linger between 8-16%. Sensor limitations also add complexity, as image quality may suffer from noise or compression artifacts. Ultimately, we need to adapt our strategies, ensuring robust detection across varying conditions for reliable outcomes.

Enhancing Detection With Illumination Sources

When we enhance color detection through effective illumination sources, we can greatly improve accuracy and reliability. Using specific illumination types like LEDs and fiber optics helps maintain ideal light quality. LEDs are energy-efficient and long-lasting, while fiber optics offer precision in tight spaces. This versatility eliminates subjectivity by providing consistent evaluations free from ambient light interference. Halogen lamps, with their high color rendering, deliver stable outputs for accurate readings. By integrating ALS sensors, we adaptively control illumination, ensuring high sensitivity and reduced false detections. In light booths, various sources can be configured, ensuring even illumination. These advancements enable automation, making processes smoother and more reliable, while consistently meeting international standards for color evaluation.

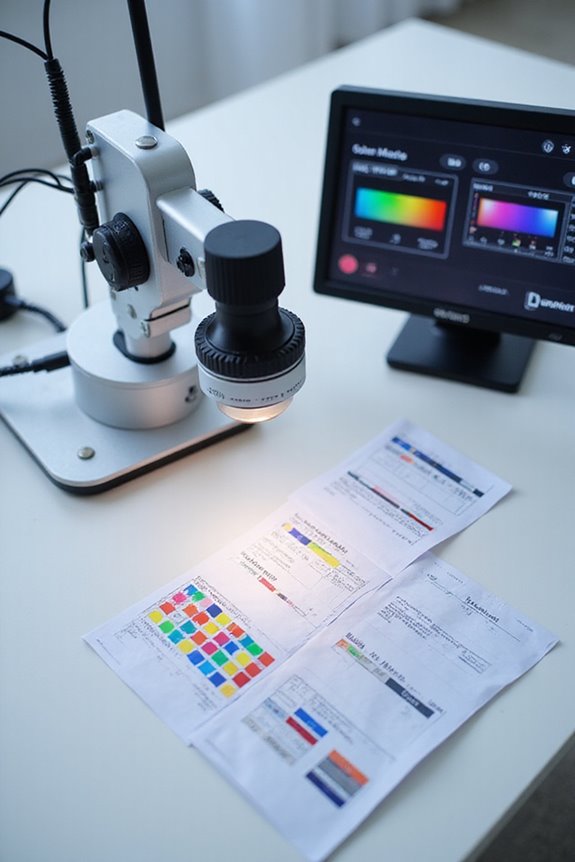

Analyzing Color Data for Practical Uses

Effective illumination enhances our ability to analyze color data for practical applications. By quantifying color data through scales and visual contrasts, we can better interpret significant trends and outliers. Color psychology plays an essential role, as different hues influence human perception and decision-making. Using tools like spectrophotometers, we achieve reliable color measurements, vital for industries from manufacturing to agriculture. For instance, in crop monitoring, analyzing leaf colors helps assess plant health. Similarly, in pharmaceuticals, consistent color detection guarantees quality packaging. By employing logical color gradations, we facilitate clearer data interpretation for diverse audiences, maximizing accessibility. Ultimately, analyzing color data allows us to make informed decisions, driving efficiency and quality across various sectors.

Future Trends in Color Detection Technology

As the demand for advanced color detection technology continues to rise, we’re witnessing exciting innovations that promise to transform various industries. The color detection sensor market is expected to reach $2.82 billion by 2029, driven by automation and the adoption of emerging technologies. AI integration enhances analysis, improving accuracy and reducing human error. Future applications in IoT, security, and smart cities will likely become integral. Multispectral imaging capabilities enable detection beyond the visible spectrum, opening doors to new materials and improved color customization. Additionally, augmented reality tools offer immersive design experiences that enhance color forecasting. By focusing on sustainability and ethical sourcing, the industry is evolving to meet modern consumer expectations, making color detection not just innovative but responsible.

Frequently Asked Questions

How Does Ambient Light Affect Color Detection Outcomes?

Imagine scanning a vibrant painting under different ambient light sources; we’ve seen how color perception variations can lead to errors. Adjusting lighting conditions is crucial to guarantee accurate color detection and consistent outcomes in our projects.

What Are Common Issues During the Calibration Process?

During the calibration process, we often encounter calibration errors arising from image alignment and device compatibility issues. These factors can lead to inconsistent results, making it challenging to achieve accurate color corrections across different setups.

Can Color Detection Work in Low-Light Conditions?

In the shadows, where darkness whispers, we can harness the power of sensor sensitivity. Yes, color detection thrives even in low light, transforming muted hues into vibrant visions, overcoming the low light impact that challenges traditional imaging.

How Do Shadows Impact Color Measurement Accuracy?

Shadows considerably impact color measurement accuracy by introducing various shadow types. To address this, we should employ measurement techniques that account for lighting inconsistencies, ensuring more reliable data even in challenging shadowed conditions.

What Are the Limitations of Color Detection Technology?

We recognize that color detection technology has notable limitations, including sensor constraints and varying environmental factors. These challenges affect our color perception, making accuracy difficult under inconsistent lighting or complex surface characteristics.